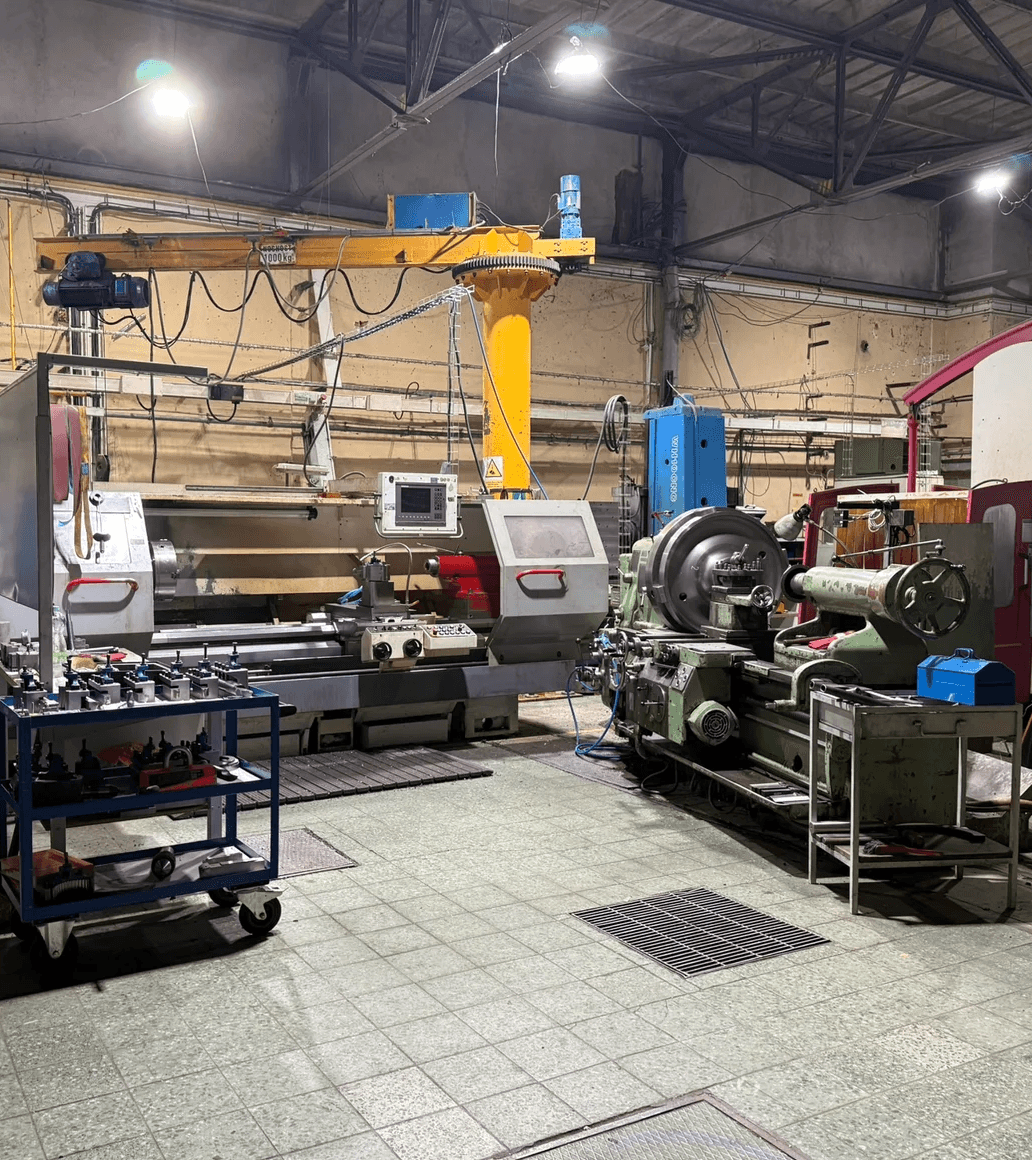

CUSTOM CNCMETAL MACHINING

Precise chip machining of parts made from various metals (steel, stainless steel, non-ferrous metals) and plastics. 3, 4 and 5-axis milling, bar turning, Wire EDM and grinding – from prototype to series.

CNC MACHINING

3/4-axis milling and bar turning. Precise parts from single pieces to series.

WE HELP WITH MANUFACTURABILITY, TEST SAMPLES, AND FINALIZE ASSEMBLY – FOCUSING ON QUALITY AND DEADLINES.

We have been manufacturing precise parts in our own facility in Jindřichův Hradec since 2016. We focus on CNC milling, turning, Wire EDM, and grinding. We supply prototypes and series orders for engineering, automotive, and manufacturing companies. We emphasize stable quality, repeatability, and clear deadlines. We also export to Germany.

CERTIFICATIONS

ISO 9001 CERTIFICATION

We maintain a certified quality management system according to ISO 9001:2016. Order traceability, First Article Inspection (FAI), CMM measurement, and measurement reports on request.

OUR SERVICES

PRECISE CNC MACHINING FROM PROTOTYPE TO SERIES

CNC MILLING

3/4 axes including horizontal. Surfaces, pockets, precise bores. Repeatability for single pieces and series.

CNC TURNING

Single piece and series production with bar feeder. External/internal operations, precise diameters and threads.

WIRE EDM

Shaped cutouts without burrs, even in hard materials. Narrow kerf, clean edges, precise tolerances.

GRINDING

Centerless and cylindrical (between centers/internal) and surface grinding. Smooth surfaces, precision in microns.

GEAR MANUFACTURING

Hobbing of spur gears and sprockets. Precise tooth geometry and repeatability.

THREAD ROLLING

Formed threads with higher strength and smooth surface. Fast and consistent series.

OUR PROCESS

HOW THE COOPERATION WORKS

-

ASSIGNMENT AND MANUFACTURABILITY

Send drawings (PDF + DXF/DWG/STEP), material, and quantity. We will verify manufacturability and propose technology and deadline.

-

PRODUCTION PREPARATION

CAM programs, tool selection, and clamping. Sample or First Article Inspection (FAI) if needed.

-

PRODUCTION AND CONTROL

Milling, turning, EDM, grinding. Inter-operational and final inspection, measurement reports on request, packaging and transport.

employees

machines in operation

pcs in series

PRECISE PARTS ON TIME. WORRY-FREE.

Milling, turning, EDM, and grinding. Get a quote within 48h.