OUR TECHNOLOGY

Modern machinery for precise chip machining. 3/4 axis milling centers (including horizontal), turning centers with bar feeder, Wire EDM cutters, grinders for final precision, CNC saws, equipment for gearing and thread rolling. Below you will find an overview of machines and their working dimensions.

CNC MILLING

CNC milling on vertical milling machines and 5D milling. We use modern control systems.

| MACHINE TYPE | TECHNOLOGICAL CAPABILITIES | QUANTITY |

|---|---|---|

| HAAS VF3 SSYT | 4-axis vertical CNC milling machine | 1× |

| MCV 1 000 | 3-axis vertical CNC milling machine | 1× |

| MAKINO A51 | 4-axis horizontal CNC milling machine, 2 pallets | 1× |

| MCU 630 V5X | 5-axis CNC milling | 1× |

| MAHO MH 600 P NC | tool milling machine | 1× |

CNC TURNING

For turning, we use single-spindle, twin-spindle, single-turret, and twin-turret CNC machines. We offer complex turning operations.

| MACHINE TYPE | TECHNOLOGICAL CAPABILITIES | QUANTITY |

|---|---|---|

| NAKAMURA WT 100 | CNC lathe – turning diameter 190 mm, turning length 500 mm, 2× turrets, driven tools, sub-spindle; Y-axis, spindle bore Ø 42 mm. LNS Hydrobar 3000 mm bar feeder, parts catcher. Qty: 3× | 3× |

| DOOSAN Puma GT 3100 | CNC lathe – turning diameter 590 mm, turning length 725 mm, spindle bore Ø 102 mm, driven tools, hydraulic tailstock. | 1× |

| YCM NTC 2000LY | CNC lathe – Y-axis, turning diameter 545 mm, turning length 570 mm, spindle bore Ø 90 mm, driven tools, hydraulic tailstock. | 1× |

| TORNADO 220 | CNC lathe – turning diameter 250 mm, turning length 500 mm, spindle bore Ø 65 mm, driven tools, hydraulic tailstock. | 1× |

| MASTURN MT 54/1500 | CNC lathe – spindle bore Ø 80 mm, swing Ø 540 mm, between centres 1,500 mm. | 1× |

| MASTURN MT 70/2000 | CNC lathe – spindle bore Ø 80 mm, swing Ø 700 mm, between centres 2,000 mm. | 1× |

| SUI 63 CNC/3500 | CNC lathe – spindle bore Ø 82 mm, turning length 3,500 mm, swing Ø 655 mm. | 1× |

| SUI50/2000 | Conventional lathe – swing Ø 500 mm, between centres 2,000 mm. | 1× |

| SU90/1000 | Conventional lathe – swing Ø 900 mm, turning length 1,000 mm. | 1× |

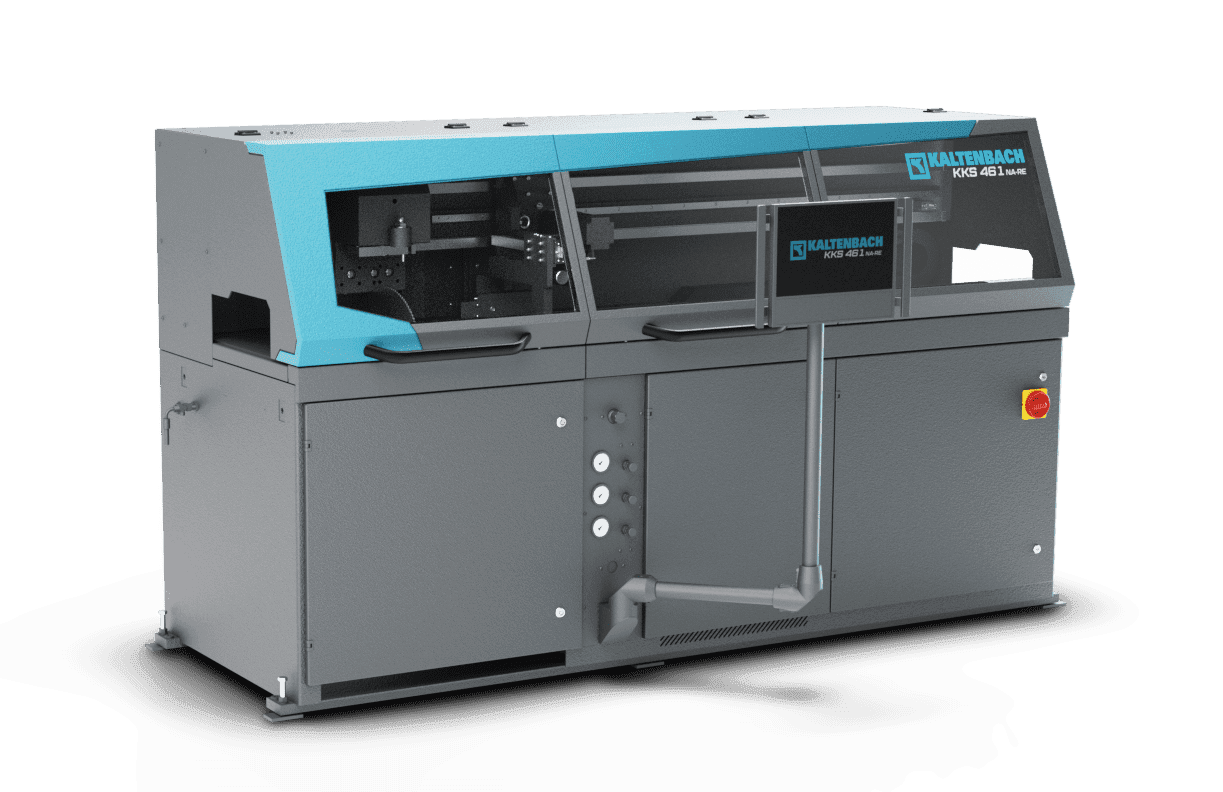

MATERIAL CUTTING

We use a CNC band saw and a CNC circular production saw.

| TYPE OF MACHINE | TECHNICAL CAPABILITIES | QTY |

|---|---|---|

| Cylindrical external grinding (between centers) | ||

| BH 40A / 1500 |

|

1× |

| BUA 20 |

|

1× |

| Internal grinding | ||

| BDU 250A |

|

1× |

| Surface grinding | ||

| ABA SL800 CNC | Ground area 400 × 800 mm | 1× |

| BPH 20NA | Ground area 200 × 600 mm | 1× |

| Centerless grinding | ||

| BB 10 | Ø = 85 mm | 2× |

| Other grinding | ||

| BN 102 | Toolroom grinder “Kameníček” | 1× |

| Gear grinding | ||

| 5B833 (Reishauer) | Productive grinding in module 0.5–4.5 | 1× |

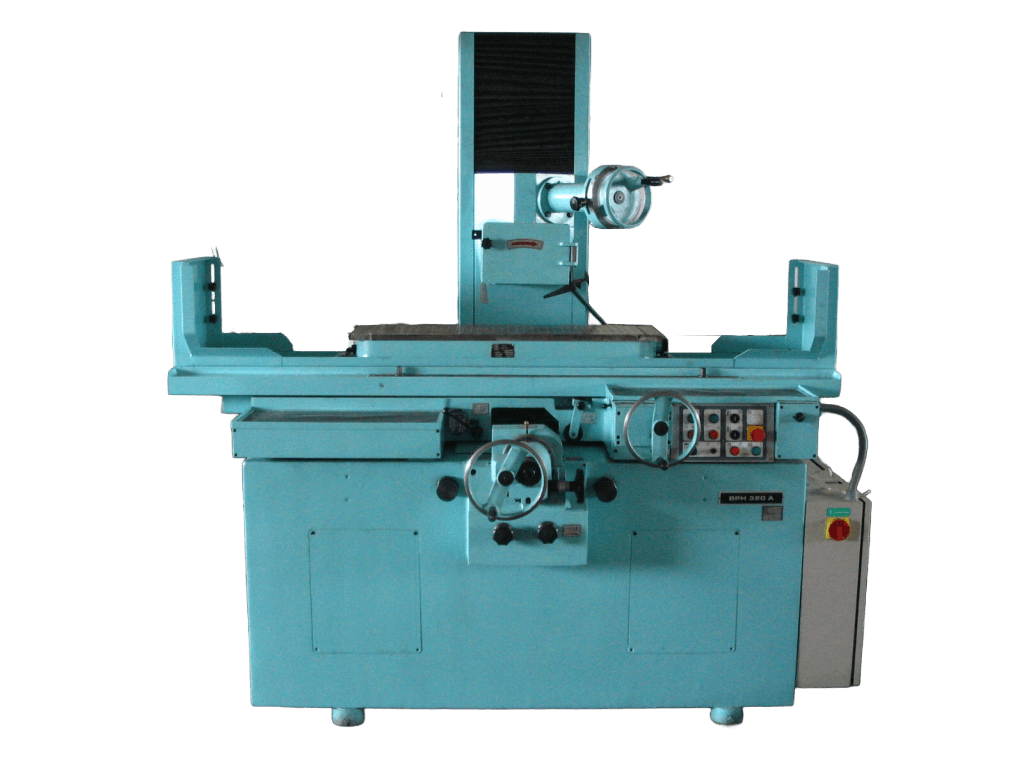

GRINDING

Grinding of external diameters, internal bores and flat surfaces.

| TYPE OF MACHINE | TECHNICAL CAPABILITIES | QTY |

|---|---|---|

| Cylindrical external grinding (between centers) | ||

| BH 40A / 1500 |

|

1× |

| BUA 20 |

|

1× |

| Internal grinding | ||

| BDU 250A |

|

1× |

| Surface grinding | ||

| ABA SL800 CNC | Ground area 400 × 800 mm | 1× |

| BPH 20NA | Ground area 200 × 600 mm | 1× |

| Centerless grinding | ||

| BB 10 | Ø = 85 mm | 2× |

| Other grinding | ||

| BN 102 | Toolroom grinder “Kameníček” | 1× |

| Gear grinding | ||

| 5B833 (Reishauer) | Productive grinding in module 0.5–4.5 | 1× |

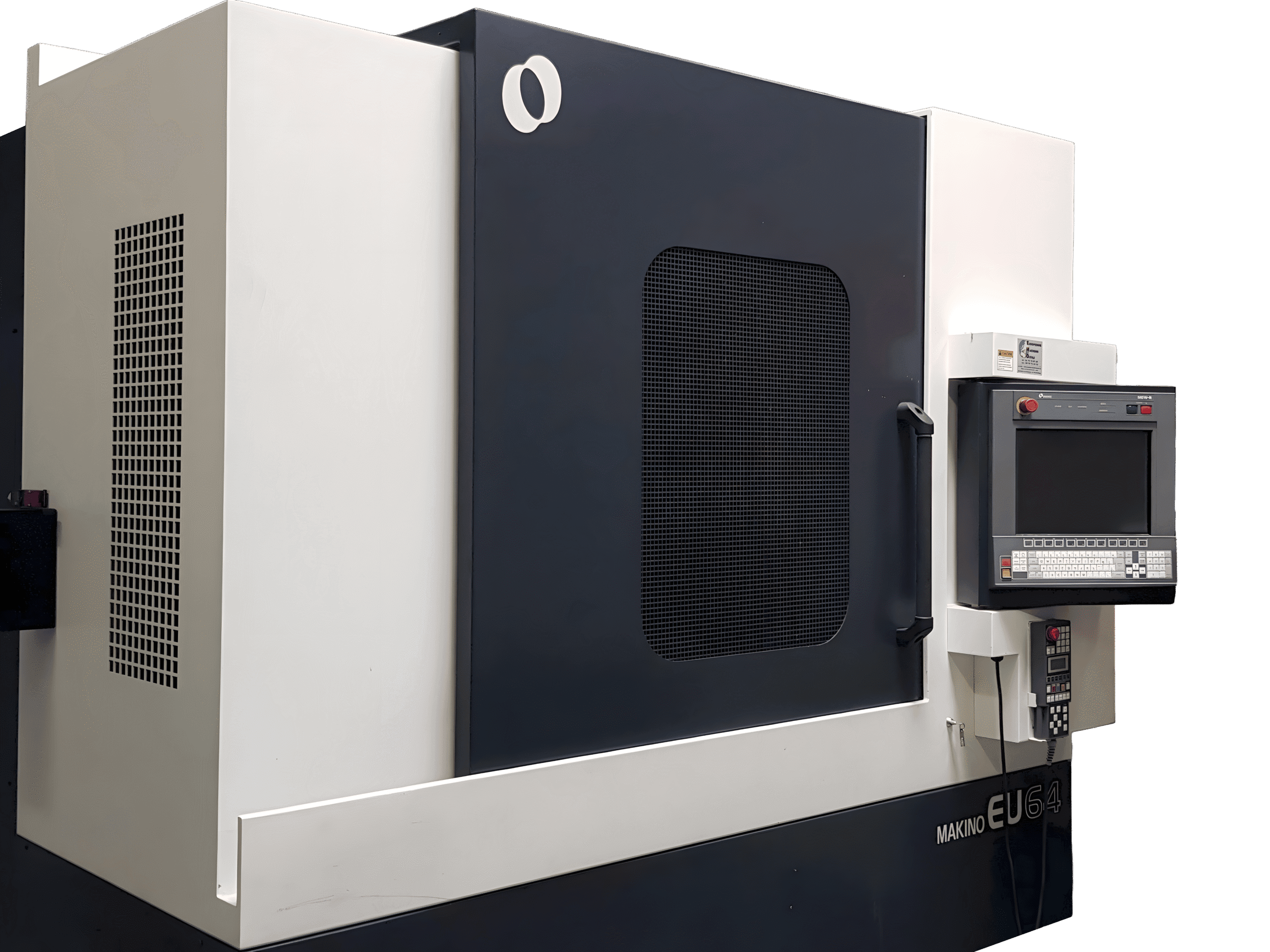

WIRE EDM

We use wire EDM for precise contour cutting of hard materials with high accuracy and clean edges.

| TYPE OF MACHINE | TECHNICAL CAPABILITIES | QTY |

|---|---|---|

| MAKINO EU64 | 600 × 400 × 260 mm | 1× |

| AGIE CHARMILLES | 300 × 200 × 300 mm (XYZ) | 1× |

GEAR MANUFACTURING

Production of spur gears, helical gears and bevel gears.

| TYPE OF MACHINE | TECHNICAL CAPABILITIES | QTY |

|---|---|---|

| OFA 75 CNC | CNC hobbing machine, max module 12, max gear blank Ø 750 mm, straight and helical teeth | 1× |

| OH 4 | Gear shaping machine, max module 4, max Ø 200 mm | 1× |

| OFA 32 A | Hobbing machine, max module 7, max Ø 320 mm, straight and helical teeth | 1× |

HEAT TREATMENT

| TYPE / PROCESS | TECHNICAL CAPABILITIES | QTY |

|---|---|---|

| Annealing | ||

| Charge parameters |

|

— |

| Induction hardening | ||

| FRITZ DÜSSELDORF | Ø 300 × 1 000 mm, medium-frequency | 1× |

| Broaching | ||

| NACHI NUV-30 |

|

1× |

We arrange heat treatments such as carburizing, hardening, nitriding, etc.

We also provide surface finishes including zinc plating, painting, blackening, hard anodizing, natural anodizing, chrome plating, nickel plating, rubber coating, and more as required.

Quality Control

| TYPE OF EQUIPMENT | TECHNICAL CAPABILITIES |

|---|---|

| MITUTOYO CRYSTA APEX C574 3D — CNC coordinate measuring machine | 500 × 700 × 400 mm |

| ROCKY 2000 Hardness Tester | |

| MITUTOYO LH 600 Digital Height Gauge | |

| MITUTOYO CV 500 Contour Graph | |

| HELIOS 350 Profile Projector |

For routine measurements in production we use standard gauges such as calipers, depth gauges, micrometers, snap gauges, bore gauges, protractors, and go/no-go gauges.

PRECISE PARTS ON TIME. WORRY-FREE.

Milling, turning, EDM, and grinding. Get a quote within 48h.